Vent Gas Condenser for SCG Chemicals in Thailand

Vent Gas Condenser for SCG Chemicals in Thailand

Chemicals Business, SCG, is one of the largest integrated petrochemical companies in Thailand and a key industry leader in Asia offers a full range of petrochemical products ranging from upstream production of olefins to downstream production of 3 main plastics resins; polyethylene, polypropylene and polyvinyl chloride.

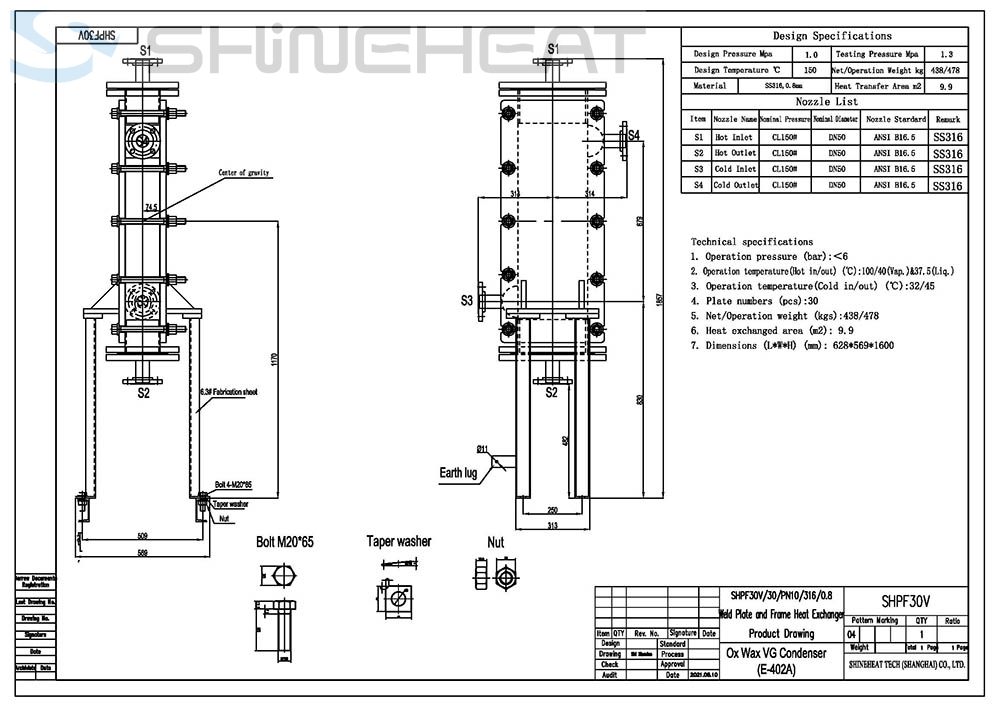

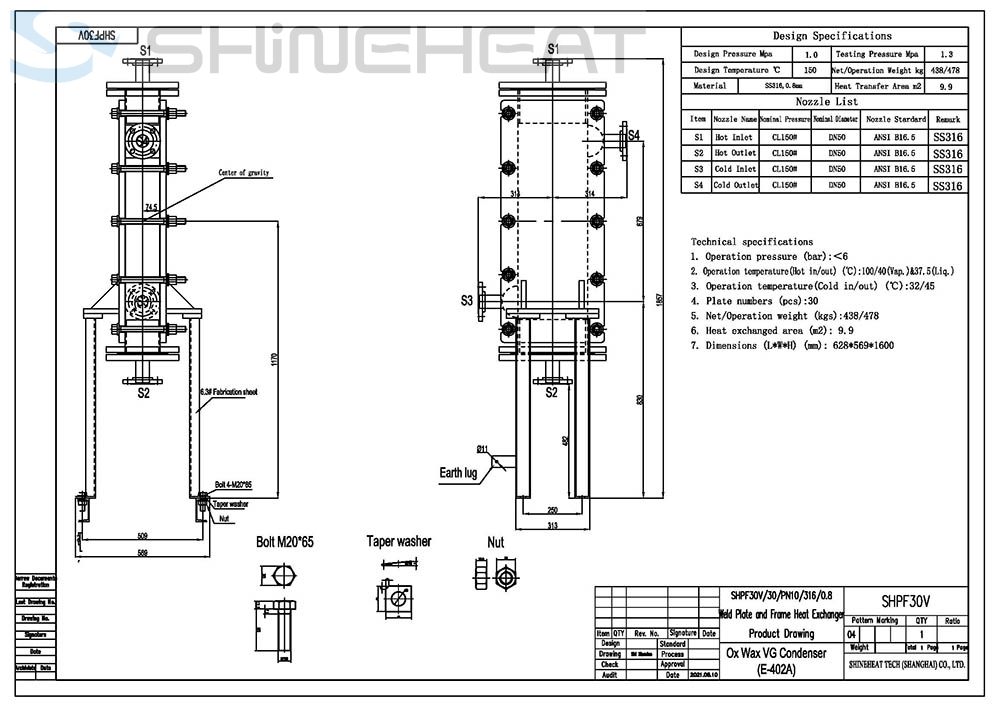

SCG had one Job for Plate Heat Exchanger to act as Vent Gas Condenser, the Vent Gas is mainly composed of 3.5% Benzene, 79% Air and 17.5% Nitrogen. The Vent Gas need to be condensate from 100℃ to 37.5℃ by 32℃ Cooling Water.

Firstly, SCG need a proposal for Plate and Gasket Heat Exchanger for this Job. After investigation the detail compositions of Vent Gas from their plant, we found a potential risk for Gaskets Corrosion by heating Vent Gas.

So our proposal for SCG is negotiated by following,

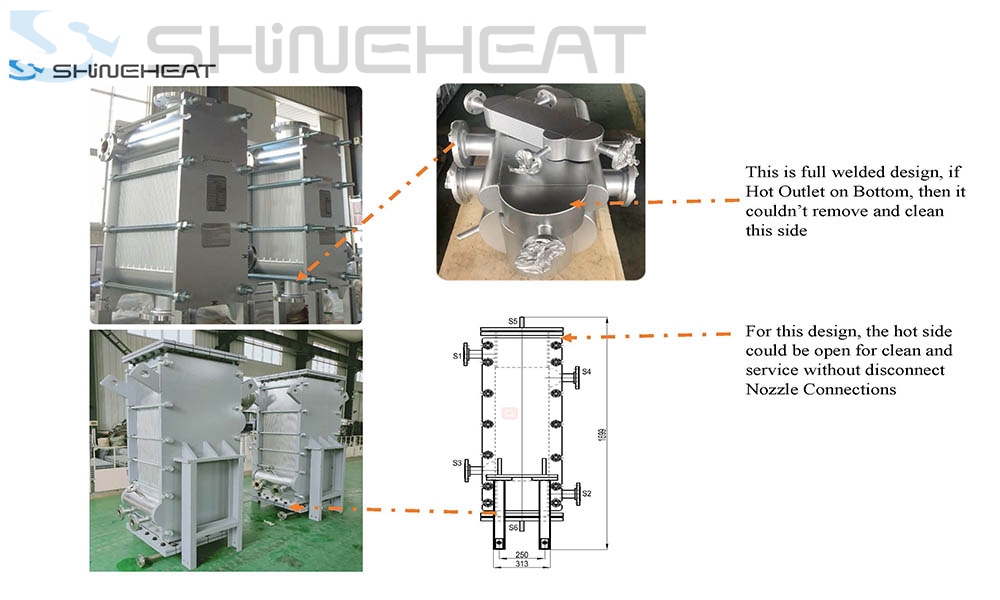

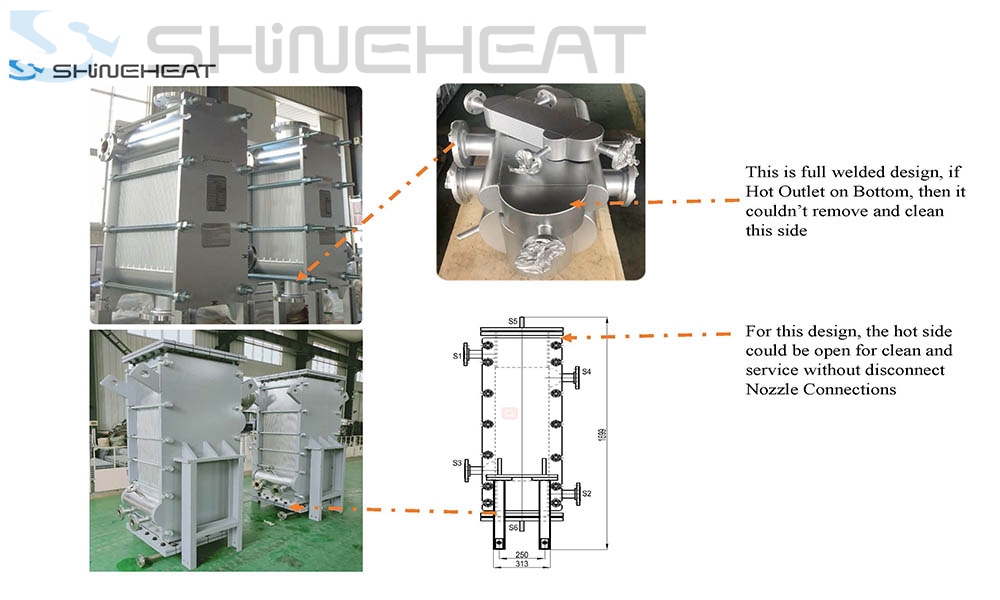

Shineheat recommended “SH-WAVE” Welded Plate and Frame Heat Exchanger for this Job, it is non-gasket type of Plate Heat Exchanger, so free-trouble of Gaskets Corrosion after some time operating;

In view of Vent Gas contains impurities which will cause fouling or coking at hot side, so Shineheat proposed openable design for Hot Side, it is convenient to open square flange to wash inside when necessary.

The Job is to completely condense the Steam in air which contains 79% of Vent Gas by cooling water, meanwhile, cooling the gas and removing smoke.

The Job is to completely condense the Steam in air which contains 79% of Vent Gas by cooling water, meanwhile, cooling the gas and removing smoke.

The Plate Condenser Working Principle, How does the SH-WAVE plate condenser work?

Plate Condenser is especially work for Vapor or Steam under Vacuum or Negative Pressure condition; the corrugated plates are with high transfer efficiency, so the structure of Plate Condenser is compact, it is ideal for installation where the space is limited, and replace Tube and Shell Type Condenser of larger and heavy type.

Shineheat Condenser is customized design according to various situation.

The Vapor or Steam Inlet Ports are very large, whereas the condensate outlets and compared small; the cold side connections are decided by process cooling media capacity, they will be also smaller than Vapor or Steam connections.

Generally, there two type of Plate Condenser in terms of sealing methods for Vacuum Side.

If Vacuum Side or Condensing Side is sealing by Welding, the Cooling Side is sealing by Gaskets, then we call it “Semi Welded Plate Condenser”, the Semi Welded Pack is called “Cassettes”.

If Vacuum Side and Cooling Side are all sealing by Gaskets, then we call it “Plate and Gasket Condenser”.

Whatever, the Plate Condenser is widely apply for Multi-Stages Evaporation System, Sugar Refinery Plant, Ethanol Condensers, Turbine Condensers in power plant.

SHINEHEAT provide ideal alternative solution for Vent Gas Condenser

Whatever power plant or chemical plant all face the problem for Vent Gas Treatment, the heat exchanger should be engaged in as a Condenser or a Cooler. Then what type of heat exchanger could be chioced for vent gas condenser or cooler?

According to experience of SCG chemical plant, firstly they used Gasketed Plate Heat Exchanger for this duty, however the gaskets of Plate Heat Exchanger need replace frequently in view of corrosion by corrosive composition in Vent Gas. The user was tired of it, not only for high maintenance cost, also for interrupting service time.

Based on SH-WAVE Welded Plate Heat Exchanger Supply, the end user could be benefit from following aspects.

- Non-Gaskets solution from SH-Wave Welded Plate Heat Exchanger, free maintenance cost;

- Earlier access for clean and flushing by openable design, save service process time;

- Initial invest cost for SH-WAVE is compared lower than other type of welded plate heat exchanger, like Shell and Tube Heat Exchanger, Plate and Shell Heat Exchanger, Compabloc Plate Heat Exchanger.

Video Demo SH-WAVE Welded Plate Heat Exchanger is under Hydraulic Test in factory